Based on the same patent and proven cutting technology of the EZ-cutter, XS & XL Cutters will enable clean and perfectly controlled cuts without using explosives, chemicals or other expensive Work-Over alternatives. Simplifying transportation, logistics and safety issues, XS and XL cutters will be easily deployable on any logging unit. The only significant requirement will be a conductive fluid in the well, like brine or sea water. After anchoring the instrument inside the casing, a quick operation to remove rust and scale deposits is initiated before supplying the electrodes with power. A controlled groove starts and deepens with time until the first perforated zone is identified. A penetration regulator then avoids the electrodes to be stuck before the end of the cut.

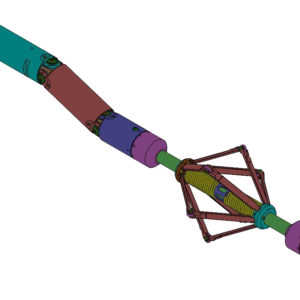

XS Cutter

XS Cutter has the objective to cut small size pipes, of nominal diameter between 2-7/8’’ and 7-5/8’’. The XS Cutter project is to integrate both Oil & Gas conditions and Well intervention technologies. It will connect on any Production logging cables.

XL Cutter

XL Cutter has the objective to cut large size diameter casings, of nominal diameter between 7’’ et 20’’. This innovative casing cutter shall integrate 12 arms mounted electrodes in order to significantly reduce the cutting times (3 hours instead of the EZ cutter 9 hours for a 45,5 lbs/ft 10-3/4’’ casing, as an example). Logging cable might be of reduced length or of larger diameter and the number of electrodes is increased in order to deal with improved cutting times.