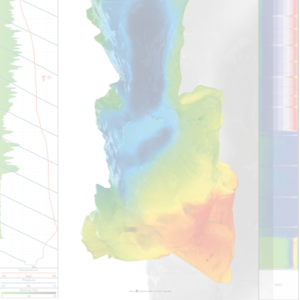

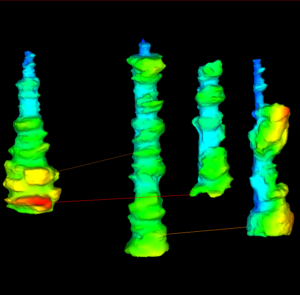

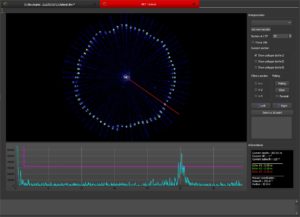

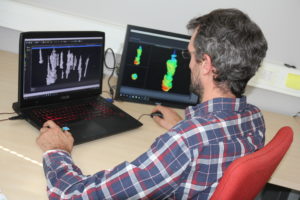

The latest cavern sonar instruments incorporate additional and upgraded sensors to bring our technology up to the highest standards with capability to run accurate deviation, depth correlation to the cemented casing, P/T versus depth

or time, and then to survey the cavern through horizontal and tilted sections, until a mesh of points is built with our engagement to have no unexplored area left.

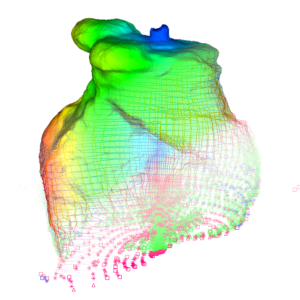

Whatever the fluid (water, brine, liquid hydrocarbons or gas), whatever the casing conditions (no pipe, one pipe or two pipes), echoes are displayed during the cavern sonar survey with distinctive colors according to their intensity. Thanks

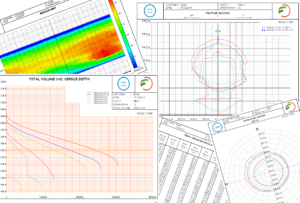

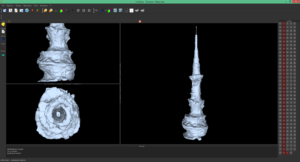

to the in-house DimCav processing software, a model of the cavern is computed to determine

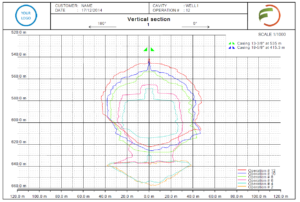

its shape and characteristics, promptly displayed after the sonar survey in a precise and clear report. The same DimCav software offers various capabilities like superposition

of plots, distances to neighboring caverns or to salt limits, and cavern field management.

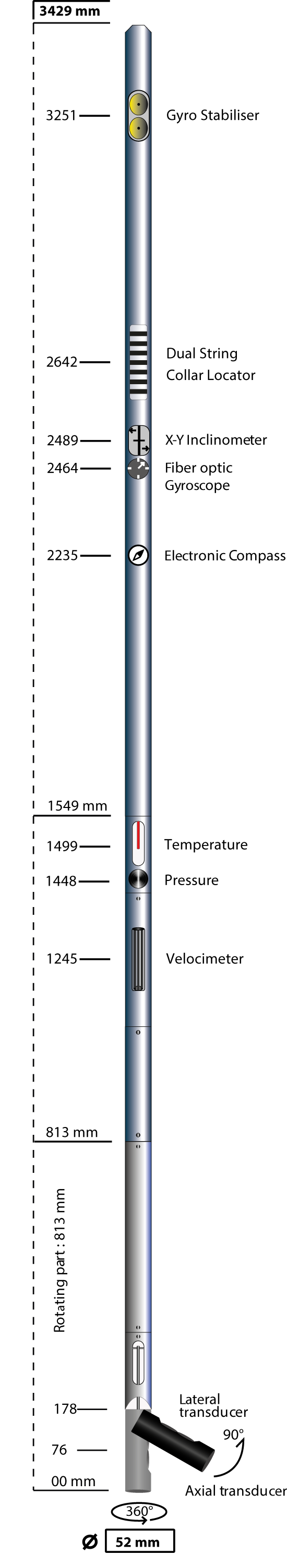

| Imperial | Metric | |

|---|---|---|

| OD | 2 ... 2-7/8" | 52 ... 73 mm |

| Length | 11.2 ... 10.6 ft | 3.43 - 3.22 m |

| Weight | 62 ... 92 lbs | 28 ... 42 kg |

| Max. Temperature | 250 °F | 120 °C |

| Max. Pressure | 5 000 psi | 350 bar |

| Max. Pressure HP sonar tool (82mm) | 10 000 psi | 700 bar |

Measuring range

Brine caverns :

0.15-250 m

H.P. Gas caverns Min. Working Pressure : 45 bar

up to100m

L.P. Gas /

Hydrocarbon caverns :

up to 80m